| Cat nr | Stock | Quantity (gr) | Price |

| Actu-TMC-100g | In stock | 100 g | €400 |

| Actu-TMC-1000g | In stock | 1 kg | On request: info@4MedChem.com |

| Actu-TMC-10kg | In stock | 10 kg | On request: info@4MedChem.com |

**Pricing disclaimer

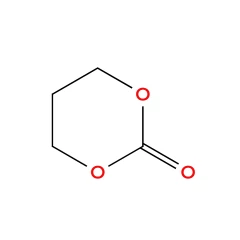

Trimethylene carbonate It is a colourless solid that upon heating or catalytic ring-opening converts to poly(trimethylene carbonate) (PTMC). This polymer is an aliphatic polycarbonate and are of interest for potential biomedical applications.

These polymers have good degradeble properties for medical applications: Engelberg, I., & Kohn, J. (1991). Physico-mechanical properties of degradable polymers used in medical applications: A comparative study. Biomaterials, 12(3), 292–304. doi:10.1016/0142-9612(91)90037-b

Trimethylene carbonate is used in Maxon suture, a monofilament strand used to suture. The material used in the device, a block copolymer of glycolic acid and trimethylene carbonate (TMC). The degradation and resorption of the Maxon suture is well described.[1]

[1] Da Mota Costa, M. R., de Abreu Oliveira, A. L., de Moura Vidal, L. W., Moran Ramos, R., de Oliveira Campos, I., Hansson, K., … Höglund, O. V. (2019). Comparison of macroscopic resorption time for a self-locking device and suture material in ovarian pedicle ligation in dogs. Veterinary Record, vetrec–2017–104732. doi:10.1136/vr.104732

Hongli Li,1 Jiangping Chang,1 Yuyue Qin,2 Yan Wu,2 Minglong Yuan,1,* and Yingjie Zhang2,*

In this work, poly(lactide-co-trimethylene carbonate) and polylactide/polytrimethylene carbonate films are prepared using a film blowing method. The process parameters, including temperature and screw speed, are studied, and the structures and properties of the P(LA-TMC) and PLA/PTMC films are investigated. The scanning electron microscope (SEM) images show that upon improving the content of TMC and PTMC, the lamellar structures of the films are obviously changed. With increasing TMC monomer or PTMC contents, the elongation at the break is improved, and the maximum is up to 525%. The water vapor permeability (WVP) results demonstrate that the WVP of the PLA/PTMC film increased with the increase in the PTMC content, whereas the WVP of the P(LA-TMC) film decreased. Thermogravimetric (TG) measurements reveal that the decomposition temperatures of the P(LA-TMC) and PLA/PTMC films decrease with increases in the TMC and PTMC contents, respectively, but the processing temperature is significantly lower than the initial decomposition temperature. P(LA-TMC) or PLA/PTMC film can extend the shelf life of apples, for instance, like commercial LDPE film used in fruit packaging in supermarkets.