- Homepage

- All Products

- Polymers - Biodegradable & Biocompatible

- L-Lactide - Cas 4511-42-6

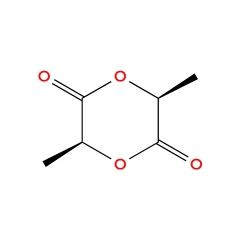

L-Lactide - Cas 4511-42-6

Product specifications

Purity: >99.5%

Name: L-3,6-Dimethyl-1,4-dioxane-2,5-dione

CAS No: 4511-42-6

Appearance: white particle

Molecular Formula: C₆H₈O₄

Molecular Weight: 144.13 g/mol

Appearance: White crystalline solid

Melting Point: ~96–98°

Solubility: Soluble in organic solvents like acetone, ethyl acetate, and chloroform; insoluble in water.

Price & Availability

| Cat nr | Stock | Quantity | Price |

|---|---|---|---|

| 250103A-5 | In stock | 5 g | €30 |

| 250103A-25 | In stock | 25 g | €130 |

| 250103A-100 | In stock | 100 g | €390 |

| 250103A-1000 | In stock | 1000 g | On request |

L-3,6-Dimethyl-1,4-dioxane-2,5-dione | Cas 4511-42-6

L-Lactide is a cyclic di-ester (dimer) of lactic acid, specifically derived from L-lactic acid, the naturally occurring enantiomer. It is an important intermediate in the production of polylactic acid (PLA), a biodegradable and biocompatible polymer widely used in medical, packaging, and textile applications.

Production & Synthesis of L-Lactide

L-Lactide is synthesized by the condensation of L-lactic acid followed by cyclization through a depolymerization process. This process occurs under controlled thermal conditions to prevent racemization, ensuring the retention of optical purity. The high-purity L-lactide is then polymerized into polylactic acid (PLA) using ring-opening polymerization (ROP) with metal-based catalysts.

Applications L-lactide

- Biodegradability: Decomposes into non-toxic lactic acid in natural environments.

- Biocompatibility: Safe for medical and pharmaceutical applications.

- Renewable Origin: Derived from plant-based sources like corn and sugarcane.

- Processing Sensitivity: Requires controlled polymerization to avoid degradation.

- Mechanical Properties: PLA from L-lactide is brittle compared to traditional plastics and may require blending with other materials for flexibility.