- Homepage

- All Products

- Polymers - Biodegradable & Biocompatible

- D-Lactide - CAS 13076-17-0

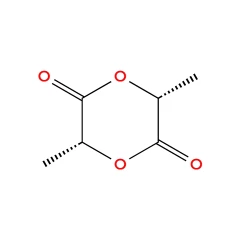

D-Lactide - CAS 13076-17-0

Product specifications

Purity: >99.5%

Name: L-3,6-Dimethyl-1,4-dioxane-2,5-dione

CAS No: 13076-17-0

Appearance: white particle

Molecular Formula: C₆H₈O₄

Molecular Weight: 144.13 g/mol

Appearance: White crystalline solid

Melting Point: ~96–98°C

Solubility: Soluble in organic solvents (e.g., chloroform, ethyl acetate, acetone); insoluble in water.

Optical Activity: Dextrorotatory (Rotates plane-polarized light to the right)

Price & Availability

Prices are available upon request with our account manager for this product: Sjonni@4MedChem.com

D-Lactide: The Enantiomer of L-Lactide for Biodegradable Polymers

D-Lactide is one of the two optically active enantiomers of lactide, derived from D-lactic acid. It is a cyclic di-ester (dimer) and serves as a key precursor in the production of poly-D-lactic acid (PDLA), a biodegradable and biocompatible polymer used in medical, pharmaceutical, and packaging applications.

Synthesis & Production

D-Lactide is synthesized through the polymerization and controlled cyclization of D-lactic acid, typically obtained from bacterial fermentation of renewable sources like corn starch or sugarcane.

The production process involves:

- Lactic Acid Formation → Microbial fermentation of D-lactic acid.

- Oligomer Formation → Condensation of D-lactic acid to form low-molecular-weight prepolymers.

- Depolymerization & Cyclization → Heating under vacuum to form high-purity D-lactide.

D-Lactide undergoes ring-opening polymerization (ROP) using catalysts such as tin(II) octoate to produce PDLA (poly-D-lactic acid).

Applications

Biodegradable Polymers (PDLA)

-

- Used in biomedical implants, biodegradable packaging, and sustainable plastics.

- When combined with PLLA (poly-L-lactic acid), it forms stereocomplex PLA, which has enhanced thermal and mechanical properties.

Medical Applications

-

- Used in resorbable sutures, orthopedic implants, and scaffolds for tissue engineering.

- PDLA degrades slower than PLLA, making it suitable for long-term applications.

High-Performance PLA (Stereocomplex PLA)

-

- Mixing PDLA with PLLA results in stereocomplex PLA, which has a higher melting point (~230°C vs. ~180°C for PLA alone).

- This enhances thermal stability, mechanical strength, and crystallinity, making it useful in automotive, electronics, and industrial applications.

Drug Delivery Systems

-

- Used in controlled drug release formulations, ensuring biodegradability and biocompatibility.

Comparison: D-Lactide vs. L-Lactide vs. DL-Lactide

| Property | D-Lactide | L-Lactide | DL-Lactide |

|---|---|---|---|

| Optical Activity | Dextrorotatory (+) | Levorotatory (-) | Racemic (±) |

| Melting Point | ~96–98°C | ~96–98°C | ~124–126°C |

| Polymer Type | Crystalline PDLA | Crystalline PLLA | Amorphous PDLLA |

| Biodegradability | Slow | Slow | Faster |

| Mechanical Strength | High (when blended with PLLA) | High | Low |

Advantages of D-Lactide

- Enhances thermal and mechanical properties when blended with PLLA (stereocomplex PLA).

- Longer degradation time, making it ideal for medical implants and drug delivery systems.

- Biocompatible and biodegradable, reducing environmental impact.

Challenges

- Requires specific fermentation processes to obtain high-purity D-lactic acid.

- Slower degradation than racemic PLA, which may not be ideal for short-term applications.

Conclusion

D-Lactide is a valuable monomer for biodegradable polymers, particularly in high-performance applications where thermal stability and strength are required. It plays a crucial role in medical, packaging, and sustainable material industries, especially when blended with PLLA to form stereocomplex PLA, offering superior mechanical properties compared to traditional PLA.